With the increasing number of people and students gaining access to 3D printing technology, we have put together this workshop as an introduction to what 3D printing is, what it's used for, and how to design the 3D models for printing.

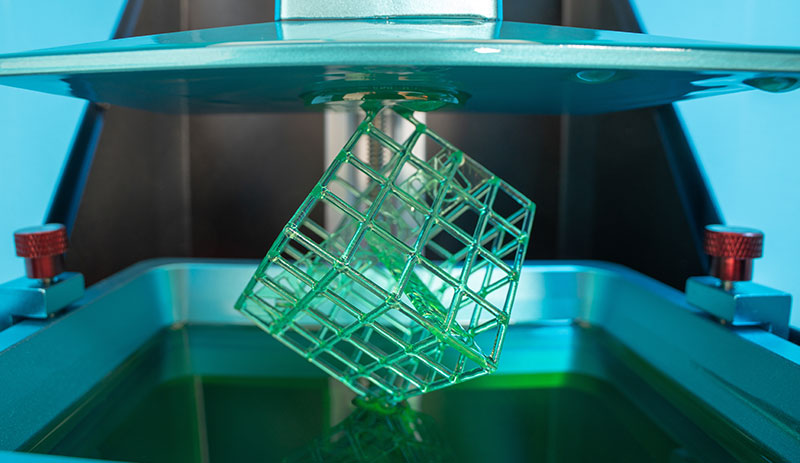

This is a completed 3D model being retrieved from a liquid photopolymer

Image from UV+EB Technology

A human ear produced using 3D bioprinting technology

Image from 3D Natives

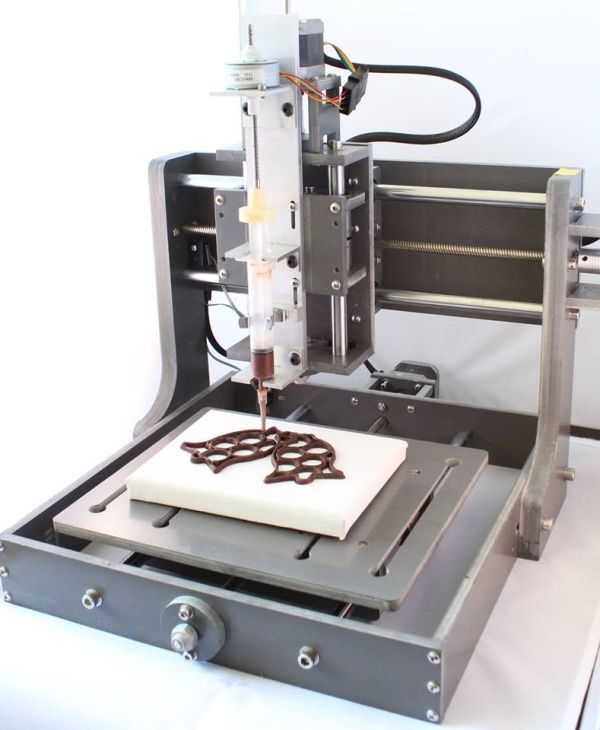

A 3D printer designed for chocolate

Image from 3Ders.org

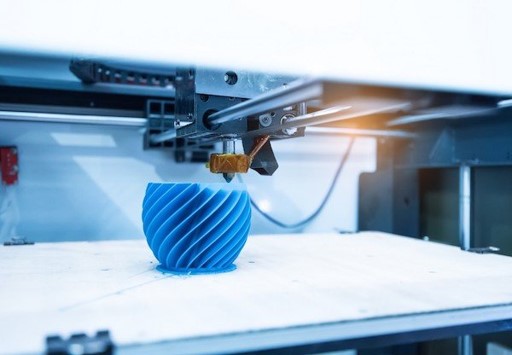

There are two different types of manufacturing when creating 3D models, they are called additive and subtractive methods

This is the production of an item by adding material. So, with 3d models it tends to involve adding layers of material until the model is complete. This means less wastage, but slower production time.

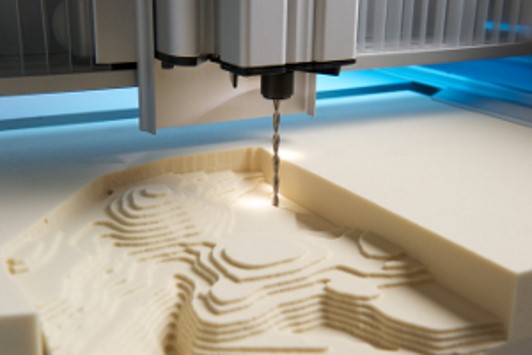

This form of production involves the removal of material. For 3D models this can invove cutting them out from a larger piece of material using routers or lasers. This means increased wastage in exchange for faster production.

We've already touched on a few examples of things 3D printing technology has been used for, this section will add to this, but will by no means be definitive.

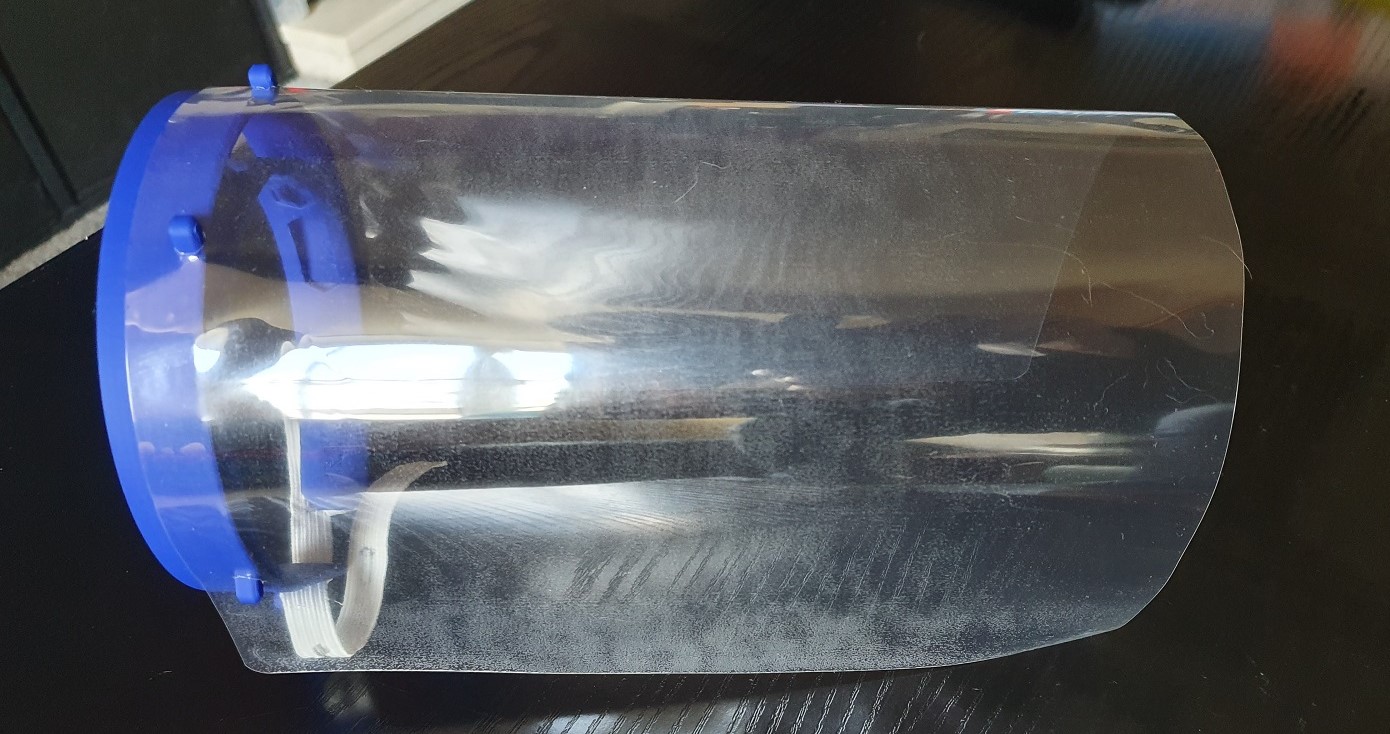

3D printers and their owners have been working hard throughout the Coronavirus crisis to assist in the production of medical supplies. Probably the most reported usage has been the production of face shields for healthcare workers. In fact, Aberystwyth University was one of many institutions, companies and individuals involved in this effort.

The above shows a completed face shield made up of three parts. The first is a 3D printed headband (the blue section), the screen is then made from sealed lamiating pouches, and the whole thing is held in place by an adjustable strip of elastic. These headbands took between 2 and 4 hours each to print (dependant on the printer).

Here is the link to the full news article about our efforts.

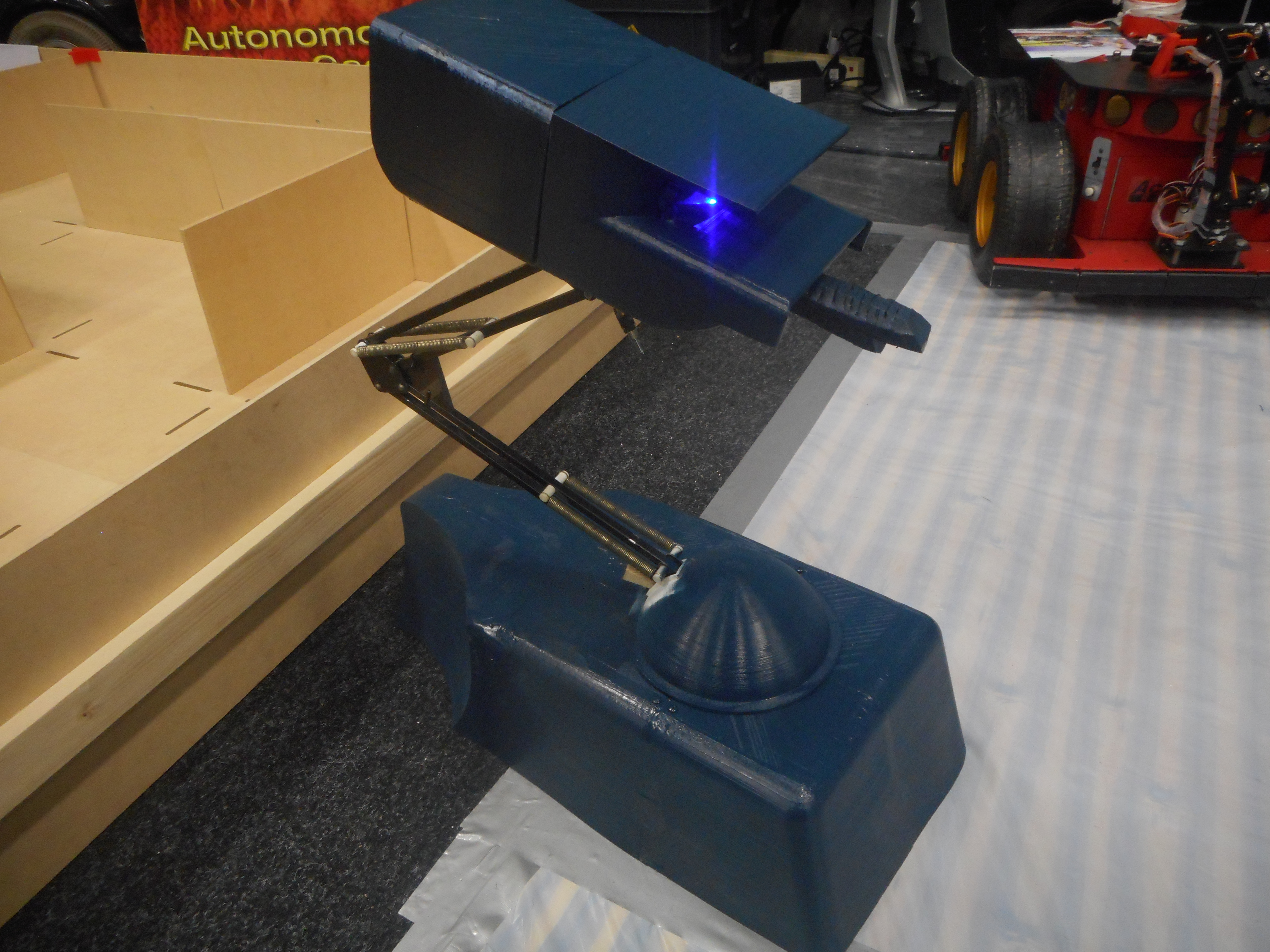

Our University has several 3D printers to produce designs for prototypes and parts for projects.

With funding from Technocamps, the Aberystwyth Robotics Club used these facilities to print and build their own InMoov humanoid robot.

One Robotics Club member has since used 3D printers to reproduce the shell of a Red Dwarf Scutter Unit for their personal project.

This is a coummunity and academic project (including researchers from Aberystwyth University) to produce 3d models of archaeological standing stone sites. Although the main aim is to produce digital models for people to explore from the comfort of their own home, the files are easily adapted for 3D printing miniature replicas of these ancient monuments.

For more information on this project visit the Heritage Together website

Below are just a few examples of what 3D printers are currently being used for. These are on top of general prototyping and manufacturing uses. For more of a taste of the wide variety of open-source designs, you may wish to browse some of the online repositories (for example Thingiverse).

There are a number of projects across the globe to use large scale 3D cement printers to make cheap housing solutions at a faster rate than conventional building techniques.

Small properties can be produced in less than 24 hours at a cheap rate due to materials and time saved.

There are a number of companies and charities that produce prosthetics using 3D printing technology to keep the costs down. These limbs are more functional than standard NHS limbs, easier to replace with a faster production time to match a child's growth and changes in taste/usage. Below is an image taken from the Open Bionics Webpage, a company that started as one man with a 3D printer and a mission to make prospthetic arms for kids more fun, functional and readily available.

Around the world, museums are starting to 3d scan all their collections. Not only is this a way of preserving the artefacts digitally, but it allows 3D printing of replicas that can be used to increase the accessibility of exhibits to people with visual impairments. Objects found in museums tend to be behind barriers or in cases, printed replicas can be handled and examined close-up without having to worry about damaging the original item. It also means exhibits can be shared virtually online, or printed to display in multiple locations at the same time.

We thought we'd end this list with a fun entry for the boost 3D printing technology has given in recent years to board and tabletop games. Companies like Kickstarter have provided a platform for creative minds to combine with 3D printing technology and interested parties for funding, to launch huge numbers of projects including a large variety of games. The 3d printers you tend to find in home and school are small units with limited print-bed space. So, when you're not using your printer to invent something, or to help save the world, why not enjoy printing miniature figures and scenery?

Whether you've designed a 3D model yourself or downloaded one from any number of open-source collections, there are a number of considerations you need to make when it comes to preparing it for printing.

There are a range of different plastics that can be used in a 3D printer. Below is a list of the most readily available materials at time of writing.

One major consideration when using additive printing is whether there are overhanging sections of the model. Printers have some flexibility for printing smaller less angled overhangs, but for anything else you will need to consider the use of scaffolding to support these sections during the printing process

Different printers come with different printing platforms (called beds). The material it is made from can affect the ability of a plastic to stick to it and stay in place during the printing process. You will probably need to trial a few test prints to establish whether a standard glue stick is enough to keep the model in place or whether you will need to add something else. Some people use hairspray instead of a glue stick, whilst others (including the author of this page) would advise trying masking tape. Most software for setting up your 3d print will include a raft and/or brim function which can also aid in adhesion.

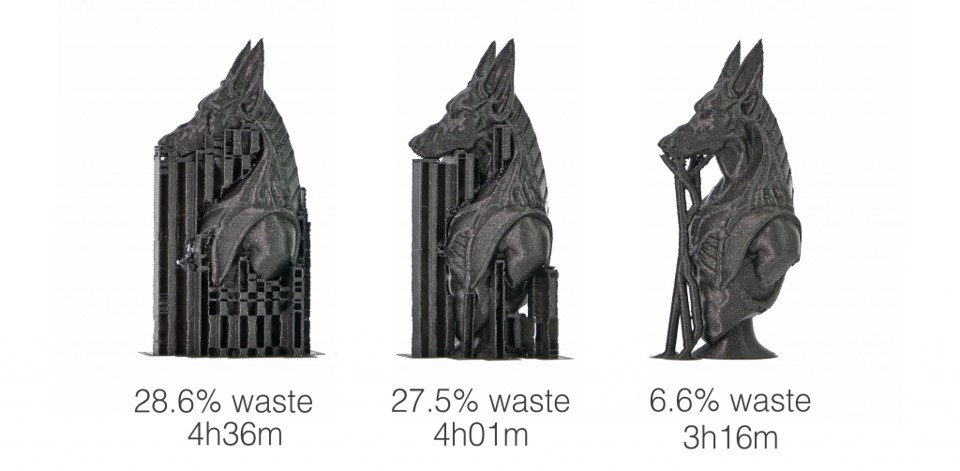

If your print does have overhangs (see above section) that cannot be avoided by rotation of the model on the print bed, then you will need to consider applying a scaffolding function. These vary according to the software you are using and how much wastage (material and time) and clean-up you are willing to deal with afterwards.

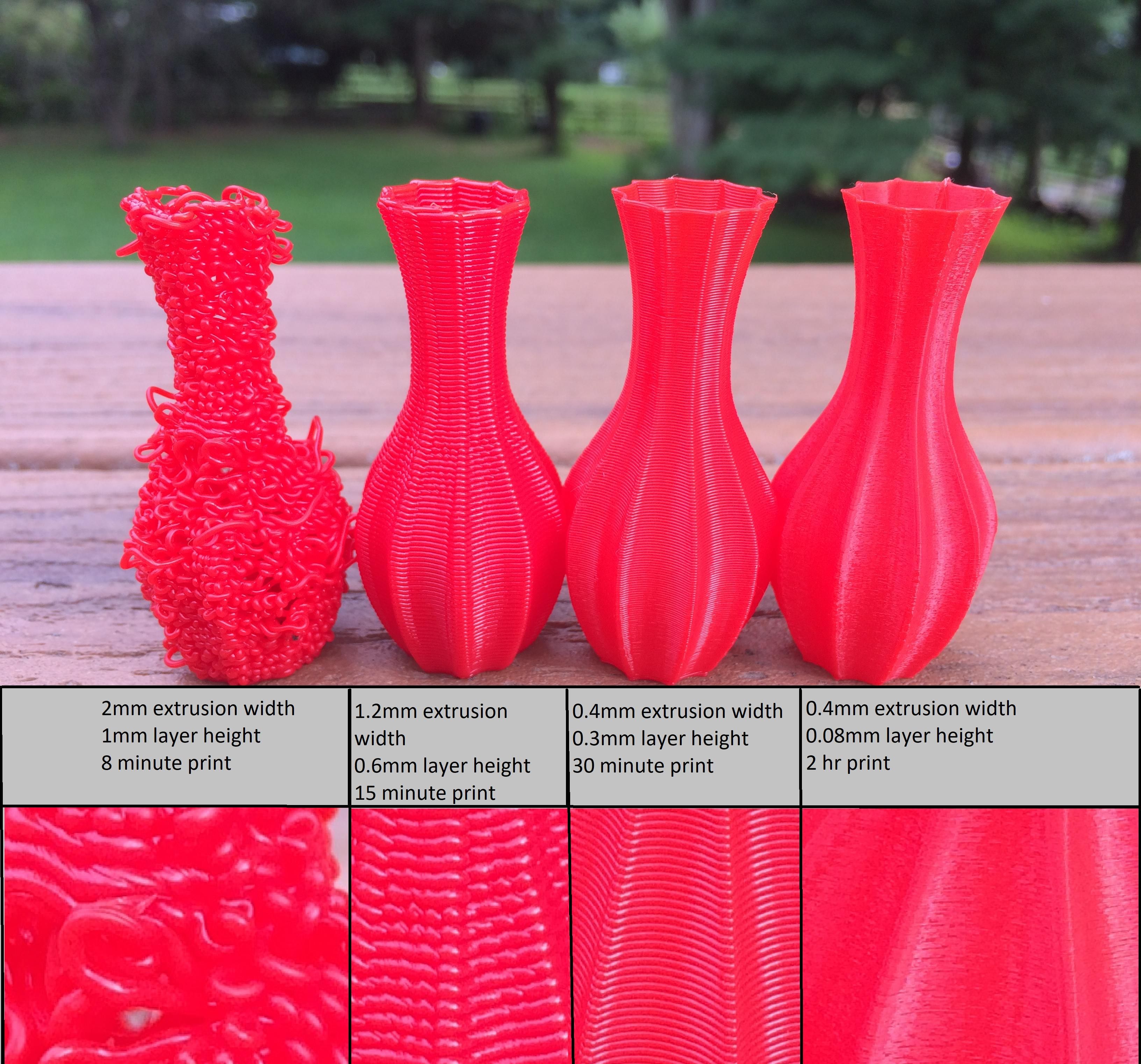

When it comes to the size of the print there are some obvious restrictions - how large is the print bed and how long do I have? Basically, the larger the print the longer it will take. You also need to consider the scaling of the model (in otherwords at what size was it initially designed for and does it scale up/down accurately). The resolution refers to the height of each layer being printed. The thinner the layers, the better the print quality. For fine detail most software will advise about 0.1mm layers, that's 10 layers per millimetre of the model! SO the better the quality, the longer the print time.

You may also notice in the above comparison that the extrusion width was also a factor. This is referring to the size of the nozzle being used by the printer. Most models have the ability to change the nozzle attachment, as long as you make the changes in your software too.

3D printing at home or in school is a slow process if you want high quality results. Most software for converting designs for printing, will give you an estimated print time. You also need to include heat-up and cool-down times. The main questions are regarding your confidence in the printer's reliability and the safety issues of leaving it running unsupervised. Large prints on home units can take days to complete.

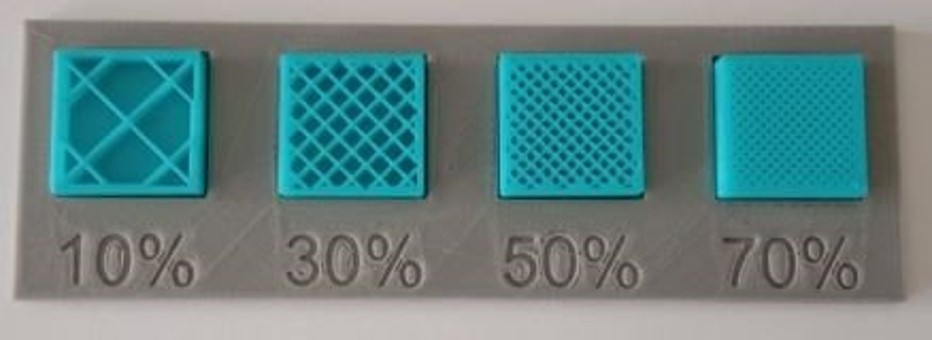

The purpose of the model is initially considered when looking at what material to use. We also need to keep it in mind when determining the in-fill of the model. That is how much plastic is inside the print. The less filling, the weaker the object but the faster the print time. On the other hand, a solid in-fill will take much longer and reduce flexibility of the model. See below for an idea of different in-fill options.